- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

Blog posts tagged with '#dscoop'

The S-One Labels & Packaging team spent the week attending Dscoop Edge Fusion, a virtual event for HP Indigo digital press users in the label, flexible packaging, and commercial print markets.

We joined more than 50 exhibitors and 3,500 attendees over four days for networking, education, and seeing the latest technology. Over in the S-OneLP booth, we highlighted our sustainable solutions from our recyclable ReTreve™ line and our bio-based ReEarth™ portfolio. We also featured an interview with Dura-Pack, a leader in the cannabis packaging space and a valued customer of S-OneLP.

S-OneLP Vice President of Sales, Tom Hauenstein, presented live on getting into flexible packaging, which can be viewed here.

As more brands are moving away from rigid containers, we see flexible packaging as a growing market, that’s already a $131 billion industry. Digital production accounts for only 1 to 2 percent of the current flexible packaging volume. However, as SKUs increase, as more brands realize the benefits of customization, and as craft brands continue to play alongside the big players, we see this segment as going nowhere but up.

The flexible packaging market comes with less competition and higher margins, so it’s no surprise that label converters are targeting this space. Many label companies are using their existing narrow web presses to produce small format pouches, sachets, and stick packs, while even more are eyeing HP Indigo’s 30-inch wide 20000 digital press, or its newest 25K digital press, for entry into this market. The manufacturer says there are 250 Indigo 20000 digital presses installed globally.

But as we heard many converters say during Dscoop, “printing is the easy part.” It’s the converting and pouching process that created an equipment and skills gap for many label converters diversifying into flexible packaging.

“It takes a while to master pouching, but there are toll pouching companies out there that can help you,” Hauenstein said in his presentation. “This is highly recommended to build a book of pouching business: Outsource first, then bring it in-house once the ROI makes sense financially.”

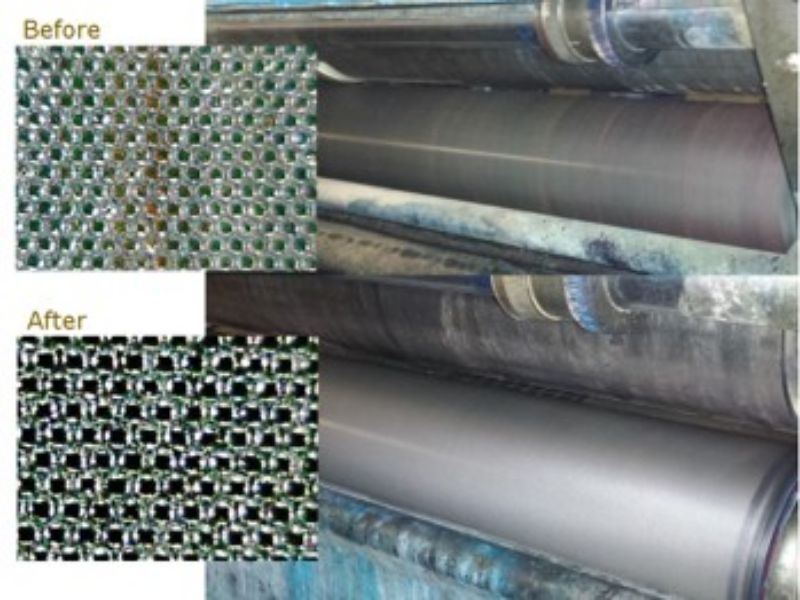

Hauenstein covered the main forms of finishing – or protecting the ink on the film’s surface. In the session, he discusses adhesive lamination, extrusion lamination, thermal lamination, and eBeam coating, and discussed at length the benefits and challenges of each.

S-OneLP offers systems for thermal lamination, via our Cellcoat T-Series, and eBeam with our CatPak™ system.

In another Dscoop session, Tom O’Brien, President of Accuflex, discussed the environmental benefits of eBeam with the CatPak system. EBeam allows converters to lose a layer of laminating material.

“We’re really glad we went with eBeam,” O’Brien said. “Upfront it costs more, but if you look at the sustainability story in flexible packaging, one of the easiest ways to tell that story is to eliminate a web of laminating film, which we’re able to do with the eBeam. We’re also doing work with bio-based films. It was the right choice for us.”

Dscoop brought attendees to a virtual visit of the Packaging Lab, another valued S-OneLP customer who also discussed the benefits of our low minimum orders, short lead times, as well as the quality of our films.

Hauenstein was thrilled to hear positive feedback from valued customers on a high-profile platform like Dscoop.

“We offer the equipment, films, and coatings necessary for the label converter to have immediate success in the flexible packaging market,” Hauenstein said.

To learn more about our products, or to get started on your flexible packaging journey, contact an S-OneLP expert today!

Flexible packaging is currently a multi-billion-dollar industry and growing every day. The demand in the consumer market has created a shift away from rigid packaging to flexible packaging.

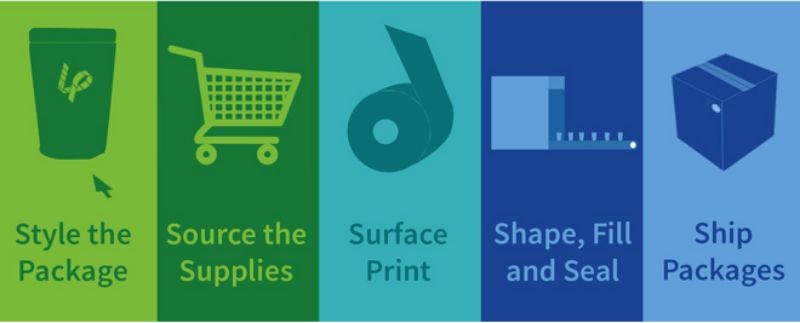

In these free webcasts, Tom Hauenstein, S-One Labels and Packaging’s Global Sales Director, takes you through two sessions about films and packaging. Get primed and ready to meet the growing demand for flexible packaging with “Boost Your Flexible Packaging Business” and “Functionality in Flexible Package Design” as Tom discusses:

- Getting into flexible packaging

- Emerging markets

- Films and laminations

- Design considerations

- Pouches vs. SnackWebs

- Product resistance

- And much more

If you have any additional questions for our team, please contact us at 941-256-7900 for U.S. & Canada and +31 43 799 5005 for EMEA or email us at labelsandpackaging@sone.com.

Join S-One Labels and Packaging’s Global Sales Director Tom Hauenstein for a PrimeTime replay as he discusses the importance of choosing the right materials for your next project.

During the 45-min live webcast, Tom explored:

- Appearance and style options for OPVs

- How application determines your varnish selection

- The importance of fast-curing adhesives

- Options for cleaners

There are a variety of options available, so watch as Tom takes you through many of them and explains the benefits of each one. After the presentation, Tom closed out the hour with a live Q&A session.

Watch the video above to see the full webcast replay.

If you have any additional questions for our team, please contact us at labelsandpackaging@sonelp.com or 941-256-7900.

The T14 Thermal Laminator, with its compact design, provides accurate tension control and high-speed capability that are ideal for digital label and flexible packaging printing and converting, especially when speed to market and minimal material waste is critical. It is ideal for HP Indigo Series 3, HP6000 series and 330mm-wide press owners.

The machine’s innovative design includes an in-line corona treater, lay-on roller, chill rollers, edge alignment and inline slitting that can all be managed by a single operator. The Cellcoat T14 Thermal Laminator is available in North America and EMEA exclusively through S-OneLP.

This is exciting technology for press operators who want to use their narrow web machines to create flexible packaging with surface-print films and provide an overlaminate to protect the ink layer and add options like soft-touch, special designs and scratch-resistance. It provides a cost-effective method in contrast to costly pressure-sensitive adhesive laminates.

Cellcoat T14 Thermal Laminator Product Highlights

- Easy settings for quick set ups for a single operator

- Short web path ideal for high-value materials (minimal waste)

- Superior bond strength

- No wet-out time required

- Ideal for: Flexible packaging, label finishing, roll stock, pouch film manufacturing, multiple film construction

Would you like to learn more about the T14 Thermal Laminator? Let us know by filling out the form below: