- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

Blog posts tagged with '#labelprinting'

The S-One Labels & Packaging team spent the week attending Dscoop Edge Fusion, a virtual event for HP Indigo digital press users in the label, flexible packaging, and commercial print markets.

We joined more than 50 exhibitors and 3,500 attendees over four days for networking, education, and seeing the latest technology. Over in the S-OneLP booth, we highlighted our sustainable solutions from our recyclable ReTreve™ line and our bio-based ReEarth™ portfolio. We also featured an interview with Dura-Pack, a leader in the cannabis packaging space and a valued customer of S-OneLP.

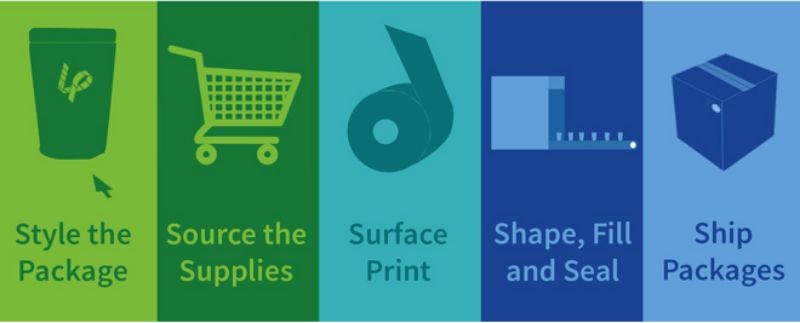

S-OneLP Vice President of Sales, Tom Hauenstein, presented live on getting into flexible packaging, which can be viewed here.

As more brands are moving away from rigid containers, we see flexible packaging as a growing market, that’s already a $131 billion industry. Digital production accounts for only 1 to 2 percent of the current flexible packaging volume. However, as SKUs increase, as more brands realize the benefits of customization, and as craft brands continue to play alongside the big players, we see this segment as going nowhere but up.

The flexible packaging market comes with less competition and higher margins, so it’s no surprise that label converters are targeting this space. Many label companies are using their existing narrow web presses to produce small format pouches, sachets, and stick packs, while even more are eyeing HP Indigo’s 30-inch wide 20000 digital press, or its newest 25K digital press, for entry into this market. The manufacturer says there are 250 Indigo 20000 digital presses installed globally.

But as we heard many converters say during Dscoop, “printing is the easy part.” It’s the converting and pouching process that created an equipment and skills gap for many label converters diversifying into flexible packaging.

“It takes a while to master pouching, but there are toll pouching companies out there that can help you,” Hauenstein said in his presentation. “This is highly recommended to build a book of pouching business: Outsource first, then bring it in-house once the ROI makes sense financially.”

Hauenstein covered the main forms of finishing – or protecting the ink on the film’s surface. In the session, he discusses adhesive lamination, extrusion lamination, thermal lamination, and eBeam coating, and discussed at length the benefits and challenges of each.

S-OneLP offers systems for thermal lamination, via our Cellcoat T-Series, and eBeam with our CatPak™ system.

In another Dscoop session, Tom O’Brien, President of Accuflex, discussed the environmental benefits of eBeam with the CatPak system. EBeam allows converters to lose a layer of laminating material.

“We’re really glad we went with eBeam,” O’Brien said. “Upfront it costs more, but if you look at the sustainability story in flexible packaging, one of the easiest ways to tell that story is to eliminate a web of laminating film, which we’re able to do with the eBeam. We’re also doing work with bio-based films. It was the right choice for us.”

Dscoop brought attendees to a virtual visit of the Packaging Lab, another valued S-OneLP customer who also discussed the benefits of our low minimum orders, short lead times, as well as the quality of our films.

Hauenstein was thrilled to hear positive feedback from valued customers on a high-profile platform like Dscoop.

“We offer the equipment, films, and coatings necessary for the label converter to have immediate success in the flexible packaging market,” Hauenstein said.

To learn more about our products, or to get started on your flexible packaging journey, contact an S-OneLP expert today!

At S-One Labels & Packaging, we value the relationships we’ve built with our vendors; we consider it the foundation of our business and our strategic partnership with Michelman is one that continues to perform – nearly 20 years and counting.

2020 was a year that tested supply chains across the label and packaging industry. As we were examining our figures from last year, something jumped out at us. While the world was grappling from a global pandemic, and supply chains were pushed to the limit, S-One Labels and Packaging and Michelman had maintained 100 percent delivery. We had not missed a single order during the height of the pandemic.

Michelman inline and offline primers for HP Indigo presses, water-based varnishes, and barrier coatings were shipped from S-OneLP in less than two days. These essential materials were shipped from S-One’s network of warehouses directly to the customer without missing a single delivery.

That means we were never out of stock of products, and our customers were able to keep their presses running – even during those chaotic early days of panic buying and stockpiling meant increased product demand and label and packaging presses at full capacity.

This flexibility and responsiveness to the marketplace has been the cornerstone of S-One’s partnership with Michelman. This relationship dates back to 2002, well before the launch of S-OneLP in 2018, and began at another S-One Division; Utopia Digital Technologies. The same was true nearly 20 years ago as is it today – Michelman were pioneers in priming on flexo presses, and Utopia chemists were technical experts for offline printing.

It was kismet.

The partnership started small, as there were very few presses in the market and not everyone had priming capability. But success was on the horizon. As HP Indigo’s business grew through the early 2000s, S-One and Michelman were able to scale with them. Over the years, this association has enabled HP digital press customers to get more out of their presses and do more with their investment.

By 2018, the digital flexible packaging market was taking off, and S-One’s label and packaging division was ready to set off on its own. In February that year, S-One Labels & Packaging officially launched as its own business unit as a channel partner for Michelman inline and offline primers for HP Indigo digital presses.

“As the channel to market partner for Michelman, our customers get the strong technical knowledge and industry expertise from S-OneLP experts, and the consistent quality that defines Michelman products,” said Tom Hauenstein, S-OneLP’s global VP of sales. “It’s is a business model that works. The partnership that S-One and Michelman set up during the past decade has helped continue our great success story today.”

Adds Pete Petrie, Sales Director, Printing & Packaging at Michelman “From the customer’s standpoint, we’ve built a partnership that serves the market better than anyone. We each focus on our core competencies and do what we do best. S-OneLP not only responds and takes care of customers, they also work with our team to provide strong technical support while we continue to be the technology innovator. The direct communication we receive from the press owners and converters through S-OneLP allows us to serve the market by developing the next generation of digital printing technology.”