- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

Blog posts tagged with '#reearth'

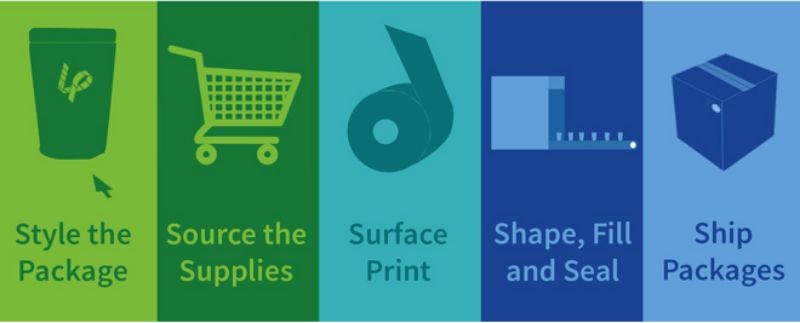

Flexible packaging is currently a multi-billion-dollar industry and growing every day. The demand in the consumer market has created a shift away from rigid packaging to flexible packaging.

In these free webcasts, Tom Hauenstein, S-One Labels and Packaging’s Global Sales Director, takes you through two sessions about films and packaging. Get primed and ready to meet the growing demand for flexible packaging with “Boost Your Flexible Packaging Business” and “Functionality in Flexible Package Design” as Tom discusses:

- Getting into flexible packaging

- Emerging markets

- Films and laminations

- Design considerations

- Pouches vs. SnackWebs

- Product resistance

- And much more

If you have any additional questions for our team, please contact us at 941-256-7900 for U.S. & Canada and +31 43 799 5005 for EMEA or email us at labelsandpackaging@sone.com.

Join S-One Labels and Packaging’s Global Sales Director Tom Hauenstein for a PrimeTime replay as he discusses the importance of choosing the right materials for your next project.

During the 45-min live webcast, Tom explored:

- Appearance and style options for OPVs

- How application determines your varnish selection

- The importance of fast-curing adhesives

- Options for cleaners

There are a variety of options available, so watch as Tom takes you through many of them and explains the benefits of each one. After the presentation, Tom closed out the hour with a live Q&A session.

Watch the video above to see the full webcast replay.

If you have any additional questions for our team, please contact us at labelsandpackaging@sonelp.com or 941-256-7900.

The T14 Thermal Laminator, with its compact design, provides accurate tension control and high-speed capability that are ideal for digital label and flexible packaging printing and converting, especially when speed to market and minimal material waste is critical. It is ideal for HP Indigo Series 3, HP6000 series and 330mm-wide press owners.

The machine’s innovative design includes an in-line corona treater, lay-on roller, chill rollers, edge alignment and inline slitting that can all be managed by a single operator. The Cellcoat T14 Thermal Laminator is available in North America and EMEA exclusively through S-OneLP.

This is exciting technology for press operators who want to use their narrow web machines to create flexible packaging with surface-print films and provide an overlaminate to protect the ink layer and add options like soft-touch, special designs and scratch-resistance. It provides a cost-effective method in contrast to costly pressure-sensitive adhesive laminates.

Cellcoat T14 Thermal Laminator Product Highlights

- Easy settings for quick set ups for a single operator

- Short web path ideal for high-value materials (minimal waste)

- Superior bond strength

- No wet-out time required

- Ideal for: Flexible packaging, label finishing, roll stock, pouch film manufacturing, multiple film construction

Would you like to learn more about the T14 Thermal Laminator? Let us know by filling out the form below:

Last fall we helped HP introduce HP Pack Ready for Labels, a fast and easy solution for creating very durable labels that can stand up to all sorts of conditions. By simply adding the Michelman DigiGuard 901 OPV Strengthener additive to a silicone-free OPV, such as KustomLP 200 Gloss or 405 Matte, you can achieve high-resistance labels that open up new market opportunities for HP Indigo printers.

In January, we printed a new batch of labels to test using the Sutherland Rub Test and tape tests that are industry-standard tests for durability. We digitally printed standard white, clear and metallized BOPP labels on an HP Indigo 6800 Press. Then, we mixed batches of DigiGuard 901 with our KKLP 200 Gloss and KKLP 405 Matte Overprint Varnish in a radio of 9 parts OPV and 1 part 901, as instructed by the HP Pack Ready for Labels process.

After a couple of days, we immersed the labels in hot water and chemicals for tests ranging from 2 to 8 hours, and then applied the Sutherland Rub Tester for 1,000 rubs with 2 pounds of pressure, at 21 cycles a minute. After these vigorous tests, we saw no visible change to the labels.

Check out the video above to see how we did it! Plus, if you’re at Dscoop Edge in Orlando, we’ll have HP Pack Ready for Labels samples in booth #305, or visit our Contact Us page to request a sample. See you in Orlando!

Introducing S-OneLP’s Sustainable ByDesign Portfolio

What better way could we honor Earth Day than to roll out the Sustainable ByDesign materials created to help reduce the impact of packaging on the world’s landfills, shorelines and oceans?

We’ve worked with the world’s top manufacturers to upend the old, ecologically damaging paradigms of food packaging with all new materials. We’re diverting used packaging away from landfills, saving emissions in transport and creating bio-based materials to eventually be recycled or composted.

Our product team has developed, tested, printed and pouched our ReEarth™ and ReTreve™ products so we can ensure they perform to the standards you expect.

ReEarth™ Bio-based Solutions:

This product line includes S-OneLP-created prelaminate composites. They can be paired with specific water-based and eBeam OPVs, which are designed to get the best performance once tested for compostability. ReEarth™ flexible packaging products that can contain cookies, chips, granola, chocolate, nuts, dried fruits, coffee, pet foods and more, include:

- Metallized Snack Web and Stand Up Pouch Surface Print Films

- Clear Stand Up Surface Print Pouch Films

- White Snack Web and Stand Up Surface Print Pouch Films

- Silver, White & Transparent Reverse Print Laminates

- Clear Sealant Monowebs

- Gloss and Matte Water-based Overprint Varnishes*

- CatPak™ eBeam Gloss, Matte and Soft Touch OPVs*

ReTreve™ Recyclable Solutions:

This line of products includes high-performing prelaminate films and OPVs that meet specific government requirements for recycling. ReTreve™ flexible packaging products that can contain cookies, chips, granola, chocolate, nuts, dried fruits, coffee, pet foods and more, include:

- White and Clear Stand Up Surface Print Films

- White and Clear High-Barrier Surface Print Film

- These films can be paired with CatPak™ eBeam Gloss, Matte and Soft Touch OPVs*

“Our goal is to bring real, sustainable solutions that will make a difference,” says Ralph Giammarco, VP of S-OneLP. “Working with our partners, we look forward to adding more sustainable products in the future. Even in the midst of dealing with COVID-19, we’re all committed to making a lasting difference.”

Our experts are available to assist with pouch constructions that meet brand requirements, so please connect with us HERE.

*Must not exceed maximum allowable limit for compostability or recyclability