Boost your productivity and enter new markets

with S-OneLP's line of capital equipment offerings

We know owning a business can be a challenge, but S-One Labels & Packaging is here to make sure your future looks brighter than ever. There are already several factors that can impact how you grow your business: taking care of customers, having the right people in place, and setting up an easy workflow, just to name a few.

Let S-OneLP take care of some of the headaches. We can help make sure you invest in the right equipment, which can dramatically improve your workflow. Here, you will learn about the T-Series thermal laminating systems, the CatPakTM eBeam System, and custom modifications to your HP Indigo press which help improve your output and performance.

T-Series Thermal Laminators

The T-Series Thermal Laminators – with their compact design – provide accurate tension control and high-speed capability that are ideal for digital label and flexible packaging printing and converting, especially when speed to market and minimal material waste is critical. They are ideal for HP Indigo Series 3, 4, 5 roll-fed Digital Presses.

The innovative design includes an in-line corona treater, lay-on roller, chill rollers, edge alignment and in-line slitting that can all be managed by a single operator. The Cellcoat T-Series Thermal Laminators are available in North America and EMEA through S-OneLP.

This is exciting technology for press operators who want to use their narrow web machines to create flexible packaging with surface-print films and provide an overlaminate to protect the ink layer and add options like soft-touch, special designs, and scratch-resistance. It provides a cost-effective method in contrast to costly self-wound over laminating film.

S-OneLP offers four models of the Cellcoat T-SeriesThermal Laminators:

T-14 - 14" (350mm)

T-21 - 21" (540mm)

T-30 - 30" (760mm)

T-43 - 43" (1100mm)

We also offer a line of T-Series validated laminate films in gloss, matte, and soft touch finishes.

Cellcoat T-Series Thermal Laminator Product Highlights

Easy settings for quick setups for a single operator

Small footprint to save you space on production floor

Short web path ideal for high-value materials (minimal waste)

Superior bond strength

Instant cure allowing you to slit or pouch immediately

Ideal for: Flexible packaging, label finishing, roll stock, pouch film manufacturing, multiple film construction

HP Indigo Modifications

The team at PCT leads the industry in solutions by bringing innovation to the field, adopting cutting-edge technologies, and expanding to new customer sectors. They create modifications for Indigo presses that will help you improve your output and performance.

Some of the modifications installed in the field include:

Backside Web Views

Dryers

Laminators

UV or AQ Coaters

What capabilities would you add to your Indigo?

From a backside web viewer to dryers, laminators, and extra take-up reels, S-OneLP and PCT can make that dream a reality.

CatPak™ System

CatPak™ is the full solution for coating and curing 30-inch flexible packaging films utilizing eBeam technology. eBeam is the state-of-the-art, high-demand finishing option for fast, clean, food-safe flex-pack films. CatPak™ brings all the key components together in one system.

Converters opt for eBeam because it offers:

A uniform, instantaneous cure

An indirect food-compliant finished surface without post-cure time

The same gloss and depth of image as reverse printed and laminated packaging

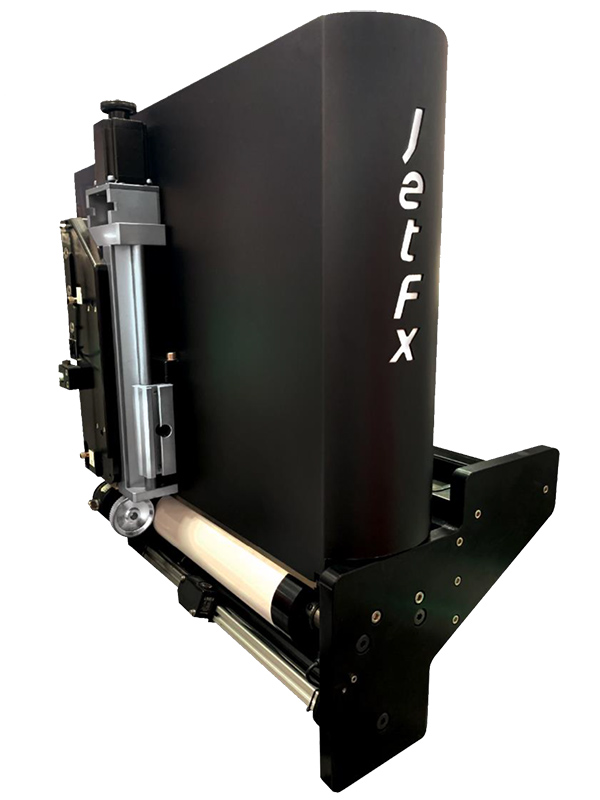

FINISHING BENEFITS: The CatPak™ System includes the eBeam coater, Corona Treater and 30-inch web unwind and rewind modules integrated into the eBeam curing system base frame. The system can also be customized to include digital embellishing equipment. Option for state of the art 30” print bar from industry leader JetFx for one-of-a-kind digital embellishments such as spot varnish and cast and cure effects.

eBeam coatings and flexible packaging films will also be available through the CatPak™ System to complete the full flex-pack printing and finishing solution.

CatPak™ System Highlights:

Compact finishing system

Instantly cured high-performance indirect food-contact compliant coatings

Speed: Up to 600 feet per minute (mechanical speed)

Patented integrated shield roll fixes the position of the web

Minimizes nitrogen flow

Easily accessible for maintenance and cleaning

Use for fully flood-coated or spot-registered eBeam coating

Works well with compostable film chemistries, i.e. Natureflex

Plus, the CatPak™ JetFx Embellishment System won’t damage HP Indigo ElectroInk, and it seamlessly supports fixtures like zippers and spouts.

CatPak™ JetFx eBeam Digital Embellishment System

CatPak™ JetFx is a proven solution for adding digital embellishment up to 30-inches wide on flexible packaging films or labels utilizing eBeam technology. eBeam is the state-of-the-art, high-demand finishing option for fast, clean, food-safe flex-pack films, shrink sleeves and labels. The CatPak™ JetFx print bar and eBeam gloss embellishment ink provide a bolt-on embellishment solution to our CatPak™ eBeam Overprint varnish system. Plus, this solution is compatible with other eBeam varnish systems.

Converters opt for eBeam embellishment because it offers:

A uniform, instantaneous cure

An indirect food-compliant finished surface without post-cure time

Inks do not contain harmful photo-initiators

The CatPak™ JetFx Digital Embellishment System utilizes a high-resolution print bar from industry leader JetFx for one-of-a-kind digital embellishments such as spot varnish and cast and cure effects.

JetFx eBeam inks, CatPak™ eBeam flood coatings and S-One LP flexible packaging films have all been validated for use with the CatPak™ System to complete the full flex-pack, shrink sleeves and labels printing and finishing solution.

CatPak™ JetFx System Highlights:

Personalize variable printing

Digital registration

Instantly cured high-performance indirect food-contact compliant ink

Speed: Up to 262 feet per minute (mechanical speed for spot varnish)

Easily accessible for maintenance and cleaning

Validated with CatPak™ eBeam flood coatings and S-One LP flexible packaging films.

Plus, the CatPak™ JetFx Embellishment System won’t damage HP Indigo ElectroInk, and it seamlessly supports fitments like zippers and spouts.

Contact our team of specialists!

Now that you have been introduced to the equipment, send us your questions or give us a call so we can provide personalized information on how you can get the most out of your investment and watch your production soar.

Contact information:

941-256-7900 (U.S. & Canada)

+49 681 93358460 (EMEA)

Für Deutsch: Renate +49 681 93358994

Para Español: Adrià +34 93 547 9722